Tank Floor MFL scanning is a non-destructive examination method which uses a magnetic field to

detect corrosion and pitting in carbon steel. A powerful magnet is scanned close to the surface to

‘saturate’ the steel with the magnetic field.

Applications

The main applications of this service are:

- On storage tank bottoms for all industries: upstream, midstream, petrochemical, refineries

- Identify soil and product side metal losses, pitting and general corrosion

Advantages

The main advantages of this service are:

- Fast method for inspecting large areas

- Minimal set-up time

- Yields reliable and economic qualitative tank floor

assessments - High sensitivity: acceptable sensitivity can be

obtained through up to 12.5 mm of combined steel and coating thickness - Only requires access to one side of the material

Equipment

Equipped with the following devices:

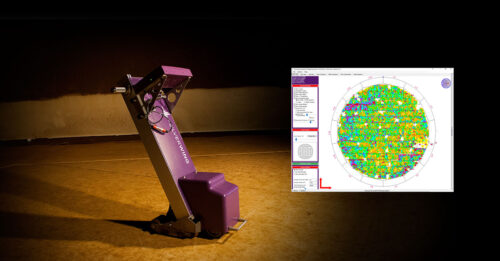

- SILVERWING (EDDYFI) Floormap 3 Di-R (64 channels)

- SIMS reporting suite, software for data interpretation and

reporting results. - Calibration plats 4, 6, 8, 10 mm thickness

Related Services

Contact Us

If you have any doubt about our services, don’t hesitate to contact us and we will respond as soon as possible.

If you have any doubt about our services, don’t hesitate to contact us and we will respond as soon as possible.