Phased Array Ultrasonic Testing (PAUT) employs advanced ultrasonic technology to conduct precise

inspections of materials and components. By electronically controlling multiple ultrasonic beams, PAUT

offers superior coverage and resolution for flaw detection and sizing. Its efficiency and accuracy make it a

cornerstone of non-destructive testing across industries, ensuring the integrity of critical assets.

Applications

This test is applicable to the following infraestructures:

- Welds and weld overlays

- Piping

- Pressure vessels

- Clad Material

- Storage tanks and structural steel

Advantages

The main advantages of this service are:

- High degree of repeatability

- Position and size data for every flaw can be compared for repeat scans of the same area to track flaw growth or corrosion rates both generally and for individual pits

- The ultrasonic beam may be both steered (change of angle),

focused and scanned without moving the probe. - Inspection can be performed on in-service equipment

Equipment

Equipped with the following devices:

- SIUI SYNCSCAN 3 (64 :128 PR) (UT/PAUT/TOFD/TFM)

- SIUI probes and wedges collection for inspection of a large

range of welding configuration and materiel including coarse

grain material (stainless steel) with DLA probe - CPS 02A Chain scanner for PAUT and/or TOFD inspection

- PA Crawler for Corrosion Mapping MPS-01A

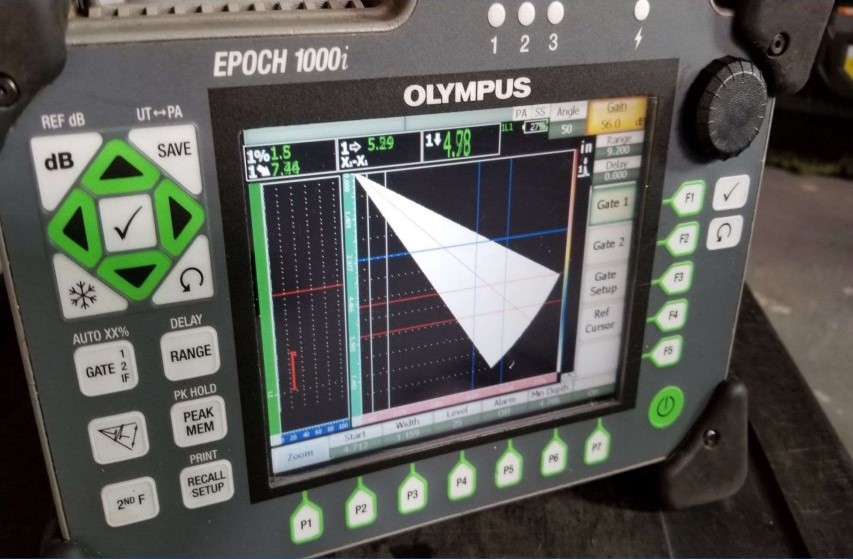

- Olympus EPOCH 1000i (UT/PAUT)

- Olympus probes and wedges collection for welding

inspection and corrosion monitoring

Related Services

Contact Us

If you have any doubt about our services, don’t hesitate to contact us and we will respond as soon as possible.

If you have any doubt about our services, don’t hesitate to contact us and we will respond as soon as possible.